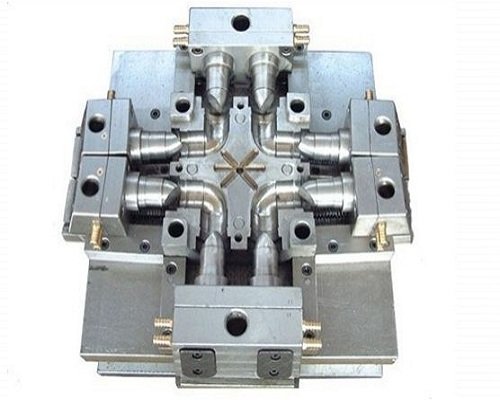

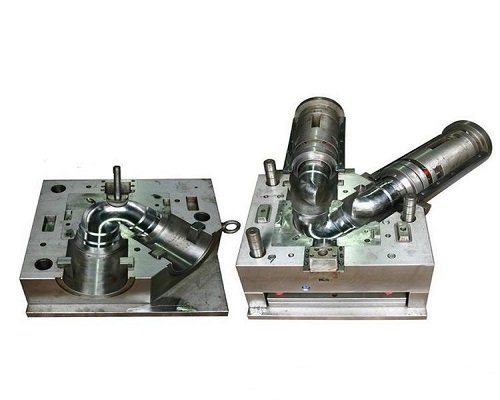

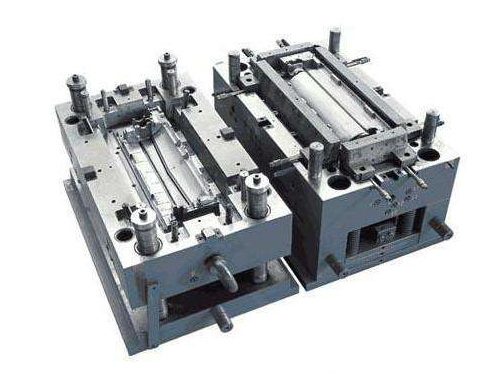

Pipe fitting mold

Item name: Pipe fitting mold

Material: PVC/PPR/PE

Size #

OEM/ODM Service #

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms: T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Pipe Fitting Mold

pipe fitting mold is a tool that is used to create various types of pipe fittings such as elbows, tees, couplings, and reducers. The mold is made up of two parts, the core, and the cavity. These parts are designed to fit together perfectly, creating a hollow space that is the exact shape and size of the pipe fitting that needs to be produced.

Importance of Pipe Fitting Mold

The use of a pipe fitting mold has revolutionized the manufacturing industry by providing cost-effective and high-quality production of pipe fittings. With the help of these molds, manufacturers can create custom fittings that meet specific requirements. This not only saves time and money but also ensures that the fittings are of the highest quality.

Types of Pipe Fitting Molds

There are two main types of pipe fitting molds: hot runner molds and cold runner molds. Hot runner molds use a heating system to keep the plastic melted while it is being injected into the mold. This type of mold is ideal for producing large volumes of pipe fittings. Cold runner molds, on the other hand, do not use a heating system. Instead, they rely on a sprue, which is a channel that connects the injection nozzle to the mold cavity. This type of mold is best for producing smaller volumes of pipe fittings.

Factors to Consider When Designing a Pipe Fitting Mold

Designing a pipe fitting mold requires careful consideration of several factors, including material selection, production volume, mold structure, and mold components.

Material Selection

The material used to make the mold is crucial to the quality of the final product. The most common materials used for pipe fitting molds are steel and aluminum. Steel molds are more durable and can handle higher volumes of production, but they are more expensive than aluminum molds. Aluminum molds are cheaper and lighter but have a shorter lifespan.

Production Volume

The volume of production is another important factor to consider when designing a pipe fitting mold. The mold design must be able to accommodate the required production volume, and the material and structure of the mold must be able to withstand the stresses of high-volume production.

Mold Structure

The mold structure should be designed to ensure the proper flow of plastic material and to minimize the risk of defects. The mold should also be easy to disassemble and reassemble for maintenance and repairs.

Mold Components

The components of the mold, including the ejector pins, cooling system, and gating system, must be carefully selected to ensure that the mold functions efficiently and produces high-quality pipe fittings.

Designing the Mold for Manufacturing Pipe Fittings

The process of designing and manufacturing a pipe fitting mold involves several steps, including creating the mold design, mold making, and mold testing.

Creating the Mold Design

The mold design is created using computer-aided design (CAD) software. The design should include all the necessary components and be optimized for the specific type of pipe fitting that is being produced.

Mold Making Process

The mold making process involves several steps, including cutting and shaping the mold components, assembling the mold, and polishing the mold surfaces to ensure a smooth finish.

Mold Testing

Before the mold is put into production, it must be tested to ensure that it functions properly and produces high-quality pipe fittings. The testing process may involve trial runs and adjustments to the mold design.

Advantages of Using a Pipe Fitting Mold

The use of a pipe fitting mold offers several advantages, including cost-effectiveness, high-quality production, and customizable production.

Cost-Effective

Using a pipe fitting mold can significantly reduce the cost of producing pipe fittings, especially when producing large volumes.

High-Quality Production

Pipe fitting molds produce high-quality fittings that are uniform in size and shape, with consistent wall thickness and minimal defects.

Customizable Production

Pipe fitting molds can be designed to produce custom fittings that meet specific requirements, including size, shape, and material.

Maintenance of Pipe Fitting Mold

Proper maintenance of the pipe fitting mold is essential to ensure that it functions properly and produces high-quality fittings.

Regular Cleaning and Lubrication

The mold should be regularly cleaned and lubricated to prevent material buildup and reduce wear on the mold components.

Inspection and Repair

Regular inspection and repair of the mold components can help identify and address any issues before they become more significant problems.

Replacement of Parts

Replacing worn or damaged mold components is essential to maintaining the quality and efficiency of the mold.

Conclusion

In conclusion, pipe fitting molds offer a cost-effective and efficient solution for the production of high-quality and customizable pipe fittings. Designing and manufacturing a pipe fitting mold requires careful consideration of several factors, including material selection, production volume, mold structure, and mold components. Proper maintenance of the mold is also crucial to ensuring that it functions properly and produces high-quality fittings.

FAQs

How do you choose the right material for a pipe fitting mold?

The material for a pipe fitting mold should be chosen based on factors such as the required production volume, the expected lifespan of the mold, and the cost of the material.

How long does it take to design and make a pipe fitting mold?

The time required to design and make a pipe fitting mold can vary depending on factors such as the complexity of the design and the production volume.

How can you extend the lifespan of a pipe fitting mold?

Regular maintenance and inspection, as well as careful use and handling of the mold, can help extend its lifespan.

What is the cost of producing pipe fittings with a mold?

The cost of producing pipe fittings with a mold can vary depending on factors such as the material, production volume, and complexity of the design.

Can you use a pipe fitting mold for different types of fittings?

A pipe fitting mold can be customized to produce different types of fittings, but it will require a different mold design and components.

In conclusion, pipe fitting molds are an important tool for manufacturing high-quality and customizable pipe fittings. Designing and manufacturing a pipe fitting mold requires careful consideration of several factors, including material selection, mold structure, and mold components. Regular maintenance and inspection of the mold are also crucial to ensure its proper functioning and longevity. By using a pipe fitting mold, companies can save on production costs while producing high-quality fittings that meet their specific needs.