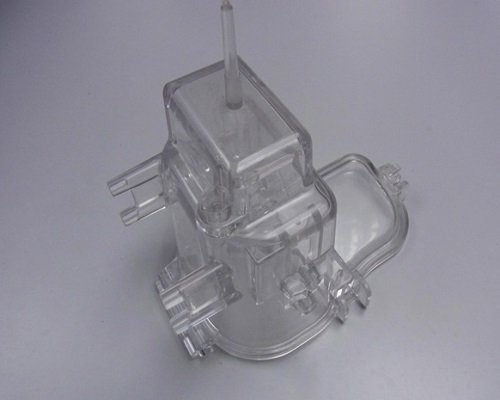

Clear Plastic Mould

Item name: Clear Plastic Mould

Material: PC/PMMA

Size #

OEM/ODM Service #

Lead time: 30-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Clear Plastic Mold

Clear plastic molding is a process of creating plastic parts that are transparent or translucent. The process involves injecting molten plastic into a mold cavity and allowing it to cool and solidify. The final product is a clear plastic part that can be used in various industries.

The Process of Clear Plastic Molding

The process of clear plastic molding involves several steps. Here are the basic steps involved in the process:

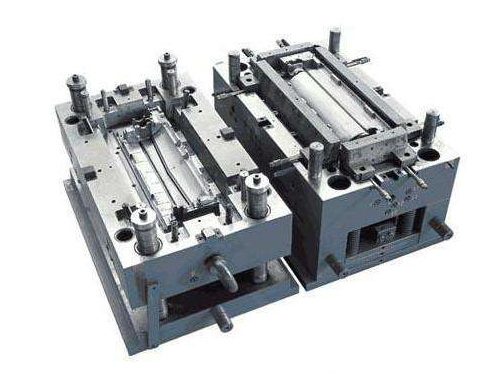

1 Preparing the Mold

The first step in clear plastic molding is preparing the mold. The mold is designed to create the desired shape of the final product. The mold is typically made of steel or aluminum and is designed with a cavity that matches the shape of the product.

2 Injection Molding

The next step is injection molding. In this step, the mold is clamped shut, and molten plastic is injected into the cavity under high pressure. The plastic fills the cavity and takes the shape of the mold.

3 Cooling

After the plastic is injected, the mold is cooled to solidify the plastic. The cooling process can take a few seconds to several minutes, depending on the size and complexity of the part.

4 Ejection

Once the plastic has solidified, the mold is opened, and the part is ejected from the mold. The final product is a clear plastic part that can be used in various industries.

Advantages of Clear Plastic Molding

Clear plastic molding offers several advantages over traditional molding methods. Here are some of the benefits of clear plastic molding:

1 Transparency

One of the most significant advantages of clear plastic molding is the transparency of the final product. Clear plastic parts allow for easy visibility and inspection of the product, which is crucial in many industries.

2 High Precision and Accuracy

Clear plastic molding allows for high precision and accuracy in the final product. The mold can be designed to create complex shapes and intricate details with high accuracy and consistency.

3 Cost-Effective

Clear plastic molding is a cost-effective alternative to traditional molding methods. The molds used in clear plastic molding are less expensive than those used in other molding methods, and the process is more efficient, resulting in lower production costs.

4 Versatility

Clear plastic molding offers versatility in design and functionality. It allows for the creation of parts in various shapes, sizes, and thicknesses. The process also allows for the use of different types of plastic materials, giving manufacturers the flexibility to choose the best material for their application.

Applications of Clear Plastic Molding

Clear plastic molding has a wide range of applications in various industries. Here are some examples of industries that use clear plastic molding:

1 Automotive Industry

The automotive industry uses clear plastic molding to create various parts such as lenses, light covers, and instrument panels. Clear plastic parts are durable and offer excellent clarity and light transmission, making them ideal for use in automotive applications.

2 Medical Industry

The medical industry uses clear plastic molding to create various parts such as syringes, medical devices, and surgical instruments. Clear plastic parts offer excellent clarity and can be sterilized, making them ideal for use in medical applications.

3 Electronics Industry

The electronics industry uses clear plastic molding to create various parts such as display screens, lenses, and housings for electronic devices. Clear plastic parts offer excellent clarity and can be made with high precision and accuracy, making them ideal for use in electronic applications.

4 Consumer Goods Industry

The consumer goods industry uses clear plastic molding to create various products such as packaging, containers, and household items. Clear plastic parts offer excellent clarity and can be made in various shapes and sizes, making them ideal for use in consumer goods applications.

6. Conclusion

Clear plastic molding is a cost-effective and versatile method of creating plastic parts that are transparent or translucent. The process offers several advantages over traditional molding methods, including transparency, high precision and accuracy, cost-effectiveness, and versatility. Clear plastic molding has a wide range of applications in various industries, including automotive, medical, electronics, and consumer goods.

7. FAQs

1. What types of plastic materials can be used in clear plastic molding?

Clear plastic molding can be done with a variety of plastic materials such as polycarbonate, acrylic, and PET. The choice of material depends on the specific application requirements such as strength, clarity, and temperature resistance.

- How long does the cooling process take in clear plastic molding?

The cooling process in clear plastic molding can take anywhere from a few seconds to several minutes depending on the size and complexity of the part. The cooling time is critical in ensuring that the part solidifies properly and maintains its shape.

- What industries use clear plastic molding?

Clear plastic molding has applications in various industries such as automotive, medical, electronics, and consumer goods. These industries use clear plastic parts for their transparency, durability, and other unique properties.

- Can clear plastic parts be sterilized?

Yes, clear plastic parts can be sterilized using various methods such as radiation, ethylene oxide, and autoclaving. The sterilization method used depends on the type of plastic material and the specific requirements of the application.

- What are some examples of products that can be made using clear plastic molding?

Clear plastic molding can be used to create a wide range of products such as lenses, light covers, instrument panels, syringes, medical devices, surgical instruments, display screens, packaging, containers, and household items.

In conclusion, clear plastic molding is an efficient and versatile method of creating high-quality transparent or translucent plastic parts. The process offers several advantages over traditional molding methods, including transparency, high precision, and accuracy, cost-effectiveness, and versatility. With its wide range of applications in various industries, clear plastic molding is a popular choice for manufacturers looking to create high-quality, durable, and aesthetically pleasing parts.