Hafo Mould is world-renowned for producing injection-molded components of the highest quality and precision at highly competitive prices. We provide all of the necessary resources to promptly and accurately complete your project from concept to completion. We offer rapid manufacturing services that include rapid prototyping services, product evaluation for manufacturability, CNC machining, injection mold, and injection molding.

Design

The design engineers at Hafo Mould have over 20 years of experience designing molds and building them. This background gives our in-house team the ability to find creative solutions to even the most challenging design manufacturing problems.

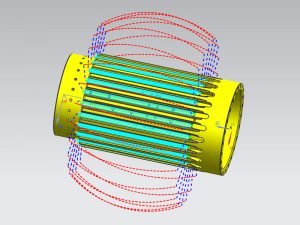

Utilizing the latest CAD / CAM / CAE, ProEngineer, and Solidworks UG design software, Hafo Mould provides customers with the best solution to shorten mold development cycles. We are known for providing customers with the highest quality mold design and production model. Innovative design solutions for molds help us stay at the forefront of mold design and engineering and bring lasting benefits to our customers.

Mold making

Hafo Mould fabricates the best tooling in the industry, and our tool warranty reinforces our claim. As long as Hafo Mould runs a tool we have built, there will never be any repair or maintenance charges. We design tools for high-volume, high-tolerance production for the life of your project. Our instruments are constructed from stainless steel mold bases and cavities, ensuring optimal performance and durability.

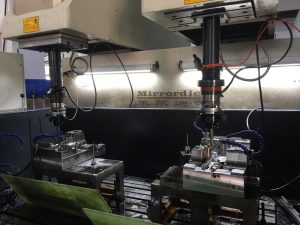

Hafo Mould is very proud of our staff. Professional mold makers mean quality can be controlled in every detail. Their knowledge and experience in the industry are unparalleled in today’s workforce. Our experienced mechanics are fully qualified to operate high-tech machinery and speed up our production process. Constant foreign exchange and internal training programs have continuously improved workers’ skills. It truly blends traditional craftsmanship with state-of-the-art technology in the mold-making process.

Injection molding service

Our facility has 30 injection molding machines, is fully automated, and with a full production schedule (24 hours, 7 days a week) during most of the year to maximize efficiency. Each press is clamping force from 46 to 720 tons. Quality control checks of product tolerances, color, and physical appearance are made at every manufacturing process step.

Whether you are looking for a one-time sample or a long-term partner, Hafo Mould has the experience and equipment to serve you from mold making to production operations. Once the project starts, the exceptional project manager will be appointed as the head of every project, from engineering, and mold making to injection molding production, to ensure smooth production.

Hafo Mould offers a full range of production moldings for short or long-term needs. We are flexible and agile to maintain the highest customer service, performance, quality, and safety. We are professionals at Insert molding and thermoset injection molding.

CNC Machining – Metal & Plastic

Hafo Mould offers a range of CNC machining services at competitive prices. Our in-house machining capabilities include sophisticated 3-axis and 5-axis robotically tended machining centers. We work with external partners to offer an even broader range of materials, component sizes, and finishes for specific applications.

As with injection molding, our sales engineers will review projects with clients when needed to assure the desired output can be achieved in the given time. Our goal is to offer our clients machining services complementary to our injection molding business that reduce our clients’ overall project management complexity. While “one-stop shopping” may be an overused phrase, we find that coordinating molding and machining for the same project yields clear benefits for our clients to assure that their complete project comes together on time.