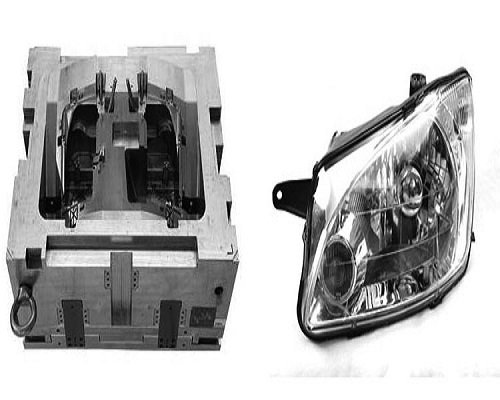

Automotive Injection Mold

Automotive injection mold is an essential tool in the automotive industry, used for manufacturing complex parts and components with precision and accuracy. It plays a crucial role in the manufacturing process, as it helps in the creation of a variety of parts such as dashboards, fenders, bumpers, and other plastic components.

Uses of Automotive Injection Mold:

The automotive industry relies heavily on injection molding technology, as it allows for the production of high-quality components in a cost-effective and efficient manner. Automotive mold is used to create parts that are lightweight, durable, and resistant to corrosion, which are crucial requirements in the automotive industry.

Automotive injection mold is used in the production of parts such as:

- Interior and exterior parts: Injection molding is used to create parts such as dashboard components, door handles, and exterior body parts such as bumpers, grills, and spoilers.

- Engine components: Injection molding is used to create components such as engine covers, air intake systems, and other parts that are essential for the proper functioning of the engine.

- Electrical components: Injection molding is used to create electrical components such as sensors, switches, and connectors.

Notes on Automotive Injection Mold:

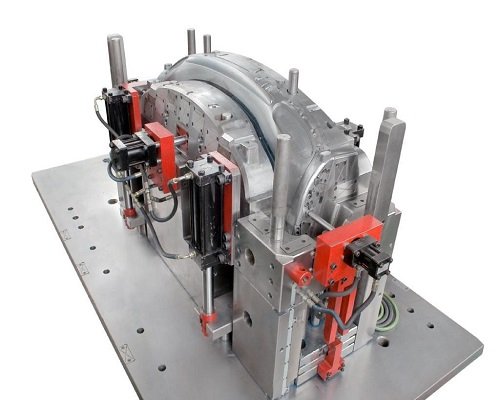

- Design considerations: The design of the mold is critical in determining the quality and precision of the parts produced. Therefore, it is essential to consider factors such as the material used, the geometry of the part, and the production volume.

- Maintenance: Proper maintenance of the mold is essential to ensure its longevity and prevent downtime. Regular cleaning and inspection of the mold can help identify issues early and prevent them from escalating.

- Quality control: Quality control measures should be implemented to ensure that the parts produced meet the required specifications and standards.

Conclusion:

The use of automotive injection mold is essential in the manufacturing of high-quality parts and components in the automotive industry. Its versatility, precision, and cost-effectiveness make it a valuable tool in the production process. To ensure its optimal performance, proper maintenance, quality control measures, and design considerations should be implemented.