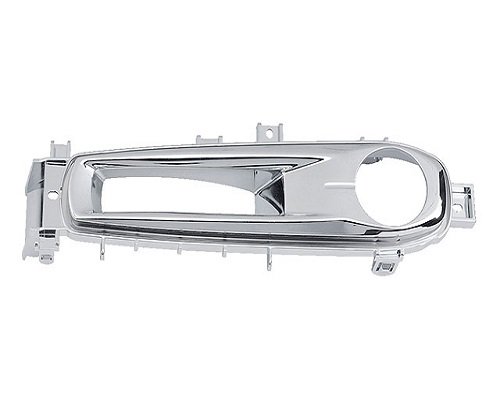

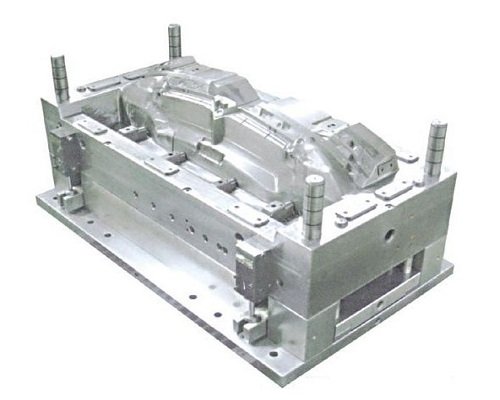

Auto Car Instrument Panels Mold

Item name: Instrument Panel Mould

Material: PE/CE/E-PVC

Size #

OEM/ODM Service #

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

How to Achieve a High-Quality Finish on Auto Car Instrument Panels Mold

Auto car instrument panels are complex parts that require precision machining to achieve the desired surface finish. A critical aspect of this process is polishing the mold surface to a high degree of smoothness.

Definition of Instrument Panels Mold Surface Roughness

The surface roughness of a mold insert is defined by two criteria: the geometry’s accuracy and the polish’s quality. The accuracy of the geometry refers to the measurement of radii and flatness, while the quality of the polish is determined by measuring the surface roughness. Surface roughness can be evaluated using several parameters, including Ra, Rz, Rmax, and Rt, which can be determined by scanning the surface using a surface roughness test instrument. For steel mold making, Rmax is typically used to meet accuracy requirements.

Systematic Polishing Technique

A high-quality finish on auto car instrument panels mold can only be achieved through a systematic and logical process of consecutive steps. The process should start with milling, grinding, lapping, and polishing to create a flat surface. Turning, grinding, lapping, polish lapping, and polishing can be used for cylindrical external surfaces. Internal cylindrical surfaces can be prepared by drilling, reaming, fine boring, honing, lapping, refining, and polishing.

The achievable surface quality is limited for each procedure. The left-sided wedge-shaped outlet of the bars means that better quality and lower surface roughness can be achieved under special conditions with most designs. The hardness and microstructure of the steel or metal surfaces to be machined should be considered, especially if high surface quality has to be achieved.

Polishing Behavior-Influencing Factors

The polishability of various automotive instrument panel mold steel grades usually depends on nonmetallic inclusions that negatively affect the polish quality due to hardness differences. Thus, the choice of automotive instrument panel mold steel is a determining factor in polish quality. Materials produced by special re-melting, degassing, or sintering processes with excellent homogeneity, high purity, and low segregation are becoming increasingly popular.

The surface quality of automotive instrument panels increases with increasing material hardness. To make machining easier, however, mild annealed steels are utilized. The ferritic structure component is disturbed when processing soft annealed steels, resulting in built-up edges, even with files with added chip spaces. Therefore, the selection of sequential machining processes has to be made to achieve the desired surface finish.

Conclusion

Achieving a high-quality finish on auto car instrument panels mold requires a systematic and logical process of consecutive steps, considering the hardness and microstructure of the steel or metal surfaces to be machined. Proper selection of the automotive instrument panels mold steel, re-melting, degassing or sintering processes, and soft annealed steels are critical factors that influence the polishing process. Following these guidelines can ensure a suitable quality surface for various auto car instrument panel mold-making applications.