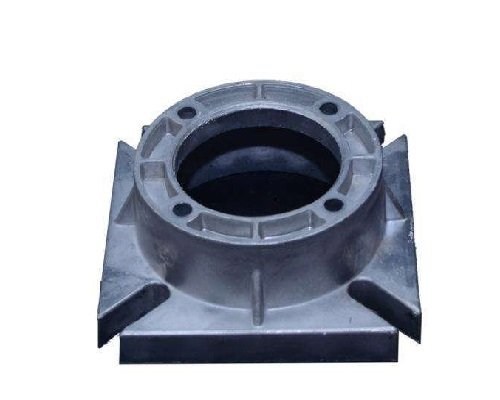

Aluminum Alloy Mould

Item name: aluminum alloy mold

Material: aluminum alloy

Size:

OEM/ODM Service

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Hafo mould have 90-1250 tons aluminum die-casting machines.Hafo mould can provide one stop service from mold design, die-casting to CNC machining, surface coating.

1. Consistent with the drawings

Aluminum alloy parts produced by die-casting molds must meet the dimensional accuracy and shape, structure, precision and technical specifications of the customer’s drawings after processing. And determine the machining site, machining allowance, process measures snd positioning criteria during machining.

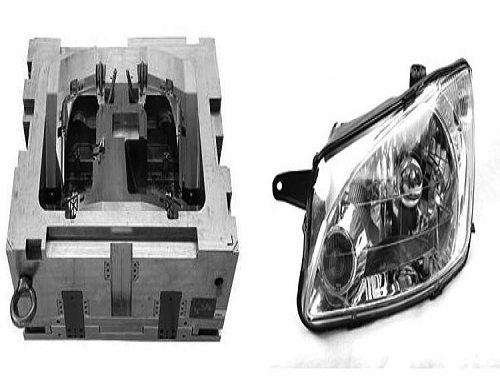

2.Simple, reasonable and reliable mold design

Aluminum alloy molding should ensure production safety, quality of aluminum alloy die-casting parts, simple, reasonable and reliable production structure, , and production efficiency is improved.

3.Parts

Mold parts should be easy to machine with CNC, milling machine, spark machine and other instruments to ensure the hardness and strength of the mold.

4.Select qualified standard parts

5.A suitable die-casting machine

Make sure injection specific pressure, calculate the clamping force, and estimate opening distance and force, pushing force, and select the accessories and tools required for die casting.