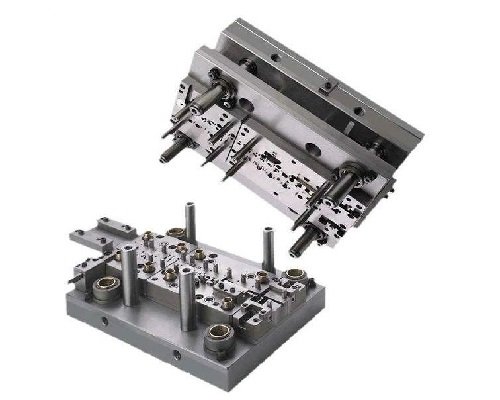

Zinc Alloy Mold

Item name: Zinc alloy mold

Material: Zinc alloy

Size:

OEM/ODM Service

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

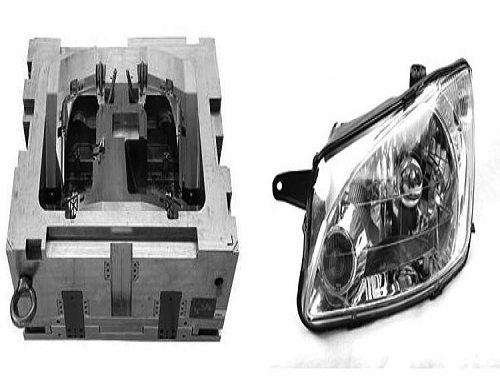

Hafo mould can produce zinc alloy dies and zinc alloy products according to the requirements of customers’ drawings.

Including Connector cover moulding, zinc alloy fittings moulding of coded lock, safe fittings moulding, safe handle parts moulding, perfume caps moulding etc.

Character of zinc alloy molding:

1.Choice of mold steel. Hafo mould recommend to use imported 8407 mold steel.

2.Runner design. Bad runner design will cause product forming is not full.

3.Design of mold insert. Bad design lead to a lot of burrs after product is formed to affect post-processing of zinc alloy products.

4.Bad slider design lead to a lot of raw edges.

5.The rationality of mold cavity, mold base and convenience of machining. Reasonable design will make zinc alloy die-casting mold production smoother and product quality can be guaranteed.