Home Appliance Molding

Molding household appliances rely on molds such as gold stamping mold, plastic mold, foaming mold, and adsorption mold. Therefore, home appliances are closely related to home appliance mold. The annual growth rate of decay required by the home appliance industry is 10%. A refrigerator requires about 350 sets of mold, worth about 700 000 USD; a fully automatic washing machine requires about 200 sets of mold, worth 5,000,000 USD; an air conditioner requires already 20 locations just for plastic mold, worth 250,000 USD; a single color TV involves a total of 140 sets of mold, worth about 1,150,000 USD. Only color TV molds have a market of approximately 500,000,000 USD every year. With the fierce competition in the home appliance market, case design has become an essential part; new requirements have been placed on the color, feel precision, and wall thickness of appliance housing. Insiders generally believe that the market will welcome large, sophisticated, well-designed (mainly thin-walled products). Therefore, some experts predict that the proportion of plastic molds in the mold will gradually increase in the future mold market, and the development speed will be higher than in other molds.

In 2009, sales of China’s plastics industry reached 100 billion USD, according to the ratio of 1:100, about 1 billion USD from the molding field. Every year, demand for household appliances and plastics reaches one million tons. Plastics are expanding in the area of home appliance applications. Various applications of plastic-based metals have made the application of plastic molds for household appliances more and more extensive. As a tool for plastic molding, nanocomposites, composite plastics, sprayable, spray-free plastics, and fiber-reinforced thermoplastics will undoubtedly provide a new world for developing plastic molds based on engineering plastics.

From the industrial layout of China’s home appliance mold, home appliance plastic mold manufacturing is concentrated in Guangdong, Zhejiang, Shandong; home appliance foam mold is focused in the Yinzhou area of Anhui, home appliance stamping mold is concentrated in Jiangsu. Around various types of mold enterprise clusters served by the large household appliance group, the supply system of home appliance enterprises is guaranteed. Chinese appliance manufacturing mold accounts for more than 80% of the market share and is entirely self-sufficient. Chinese mold manufacturing companies are fully capable of producing mold with high molding requirements, such as large LCD TV plastic mold and back sheet stamping dies.

In 2010, under China’s rapid economic growth and global economic recovery, China’s mold industry achieved good recovery growth in the post-crisis period. The total mold sales nationwide reached about 20 billion USD, a 14% year-on-year increase. According to customs statistics, molds’ full import and export in 2010 reached 4.258 billion US dollars. Among them, mold import was 2.196 billion US dollars, an increase of 19.15%, and mold export was 2.062 billion US dollars, an increase of 4.99%. In China’s mold export areas, in addition to the traditional US, Japan, and European and Southeast Asian markets, the development of emerging markets such as Brazil, India, Russia, and Australia has achieved results. China’s mold exports have reached more than 40 countries and regions. According to customs statistics, mold exports mainly come from Guangdong, Zhejiang, and Jiangsu, followed by Shanghai, Shandong, Fujian, Tianjin, Liaoning, Beijing, and Jilin. It can be seen that the Pearl River Delta, the Yangtze River Delta, and the Beijing-Tianjin region are still producing areas for mold production and also for home appliances. The place where the mold is concentrated. In 2010, China exported 503 million US dollars of stamping dies, 1.514 billion US dollars of rubber and plastic molds, and 178 million US dollars of other molds. It can be seen that the advantages of China’s mold industry are still mainly reflected in rubber and plastic mold, which also reflects the intense competitiveness of home appliance mold. The market is more active. During this period, the growth rate of mold exports was higher than the industry’s overall growth rate, and for the first time, it achieved a good result in the annual foreign trade surplus.

In May of the Lunar New Year and the Gregorian calendar in June, China Mould Industry Association will hold the China International Mould Technology and Equipment Exhibition in Shanghai. At this 70,000 square meter exhibition, 800 mold companies are exhibiting. It will provide manufacturing companies with a choice of mold suppliers and exchange of forming technology. It will also hold various technology and solution case exchanges for related products and build a multi-level communication enterprise platform.

On home appliance mold, Have Mould

- High-speed machining technology is widely used

High-speed machining is generally used for large-scale home appliance cover mold, and its surface machining accuracy can reach 0.01mm. The high-speed milling and finishing of home appliance mold surface can be used only with a bit of polishing to save time for grinding and polishing. High-speed machining significantly shortens the molding cycle, increasing the product’s market competitiveness.

European and American mold companies use CNC high-speed milling, with a five-axis linkage, and spindle rotation is generally 15000-30000r/min. In addition, European and American mold companies also attach great importance to equipment renewal, equipment depreciation period is typically 4-5 years. The addition of CNC high-speed milling machines is one of the critical points of equipment investment in mold enterprises.

- High-speed scanner and mold scanning system

A high-speed scanner and mold scanning system provide many required functions, from a model or physical scanning to processing the desired model, significantly shortening the home appliance mold development and manufacturing cycle. Some fast scanning systems can be quickly installed on existing CNC milling machine centers to achieve rapid data acquisition, automatic generation of various CNC system processing programs, CAD data in different formats, and reverse engineering for mold manufacturing.

Mold scanning system has been successfully applied in Europe and the United States industries.

Further development of hot runners and gas-assisted mold

More than 80% of plastic mold produced by many foreign injection mold manufacturers use hot runner technology, and the effect is pronounced. Many companies in Europe and the United States have successfully used gas-assisted technology on TV casings, washing machine casings, and mold for thick-walled plastic parts. Gas-assisted injection molding has the advantages of low injection pressure, slight warping deformation of products, good surface quality, and ease of forming a product with a significant difference in wall thickness, which can significantly reduce the cost under the premise of ensuring product quality.

- Combination of rapid prototyping technology and rapid tooling technology

Competition in the home appliance market is increasingly fierce, and product renewals are accelerating. The combination of rapid prototyping technology and rapid tooling technology is applied to mold manufacturing; that is, the prototype of product parts is manufactured by fast prototyping technology, and the mold is quickly manufactured based on the prototype. RP and RT technology application from mold design to manufacturing is only about 1/3 and 1/4 of traditional processing and fee costs.

Many home appliance mold manufacturers in Europe and America use rapid prototyping of silicone rubber mold for a small number of plastic parts, which is very suitable for trial production. Some countries in Europe and America also use aluminum to make injection molds, which can shorten the cycle range of injection molds by 25-30%, significantly reducing the weight of home appliance molds and shortening grinding and polishing time by half. Germany has developed a reinforced plastic for the cavity and core of plastic mold with a life of more than 100,000 pieces.

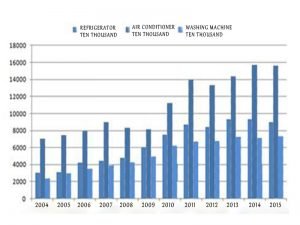

Since 2012, China’s home appliance industry has maintained a high-speed growth momentum. Affected by this, the home appliance plastic mold industry, which plays a vital role in the innovation and scale production of home appliances, has also developed rapidly.

With fierce competition in the home appliance market, mold manufacturing has become an essential part of the existing design of complex and precise requirements. At the same time, new requirements are placed on the color, feel precision, and wall thickness of the appliance casing. As the product is updated faster and new products are emerging, the overall case of home appliances is developing in a thin, light, and delicate direction. New technology is changing with each passing day, which improves the molding process in full swing. The use of mold has become broader and broader, and requirements for mold are getting higher and higher. The composite forming of metal and non-metal materials, precision ultra-precision forming, special forming, intelligent forming process, and technology research have realized many traditional methods such as alternative spraying. New products of green materials and mold enable home appliance companies to obtain strong molding equipment support.

Data shows that the annual demand for household appliances and plastics reaches one million tons. With the continuous expansion of plastics in-home appliance applications, various applications of plastic-based metals have made the application of home appliance plastic mold more and more extensive. In addition, the trend of the Chinese appliance industry to the high-end development, home appliance plastic mold will present a “blowout” situation for a long time.

In this regard, the association’s person Luo Baihui pointed out that with the capacity demand of the home appliance industry, the development prospects of the plastic mold industry, especially the home appliance plastic mold industry, are undoubtedly excellent. On the one hand, from the current market situation, as equipment support for plastic molding, the strategic position of home appliance plastic mold is constantly highlighted. At the same time, the application of nanocomposites, composite plastics, sprayable, spray-free plastics, fiber-reinforced thermoplastics, etc., will undoubtedly provide a new world for the development of plastic mold based on engineering plastic.

On the other hand, the necessity for transforming the home appliance industry has also driven the deep development of the home appliance plastic mold industry. It is understood that current large-scale, sophisticated, well-designed injection molds have received more and more attention from home appliance companies, large LCD TV plastic molds, back sheet stamping dies, and other molds with higher molding requirements have undoubtedly put forward higher requirements and tests for the domestic plastic mold industry.

With the ride of the home appliance industry, the plastic mold industry is opening a new journey. Luo Baihui pointed out that as market demand continues to release, the development space of the plastic mold industry will be even greater. Domestic plastic mold enterprises must firmly grasp the development opportunities and develop more products that meet the market demand to be more favorable in future market competition.

With the increasing size of home appliances, “multi-cavity” developed to improve production efficiency has also led to a growing measure of home appliance mold. At the same time, the rapid development of home appliances and electronics has also brought about miniaturization and precision of parts. Some home appliance mold processing tolerances are required to be less than 1μm. Therefore, actively adopting advanced equipment and improving the level of home appliance mold manufacturing can achieve significant economic benefits.