Automotive Molding

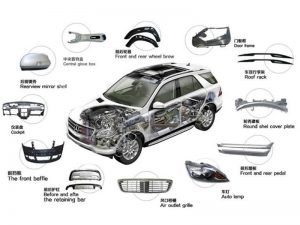

The auto parts industry is the foundation and an essential part of the development of the automotive industry. There are about 30,000 parts in the whole vehicle. It can be divided into regions of automotive engine, automotive body, chassis, electrical and electronic equipment, and general-purpose parts according to the functions. The material classification can be divided into metal parts and non-metal parts, of which metal parts account for about 60%-70%, and non-metal factors account for approximately 30%-40%.

Automotive mold refers to the mold used in the automotive field and is the “mother of the automotive industry.” More than 90% of parts in automotive production rely on mold forming.

Generally, it takes more than 1,000 to 1,500 sets of stamping dies for a car, which accounts for about 40% of the total output value of the entire vehicle. There are approximately 800 sets of plastic mold, 300 pairs of sheet metal mold, and 100 sets of die-casting mold. Automotive stamping molds are critical technological equipment for automotive production. Their design and manufacturing time accounts for about 2/3 of the whole automotive development cycle, which becomes one of the main constraints. Automotive stamping dies have the characteristics of considerable size, complicated working surface, and high technical standards and belong to technically intensive products.

Stamping on automotive bodies are broadly divided into cover panels, beam panels, and general stamping panel. A stamping that can represent the characteristics of a car is an automotive panel. Therefore, the more specific automotive mold can be an “automotive panel stamping die.” Simply as automotive mold.

Large and medium-sized cover automotive mold is an essential part of body manufacturing technology and a pivotal link to forming independent development capability of automotive. Automotive mold products include automotive cover mold, tire mold, plastic interior, exterior mold, automotive lamp mold, automotive bumper mold, and instrument panel mold.

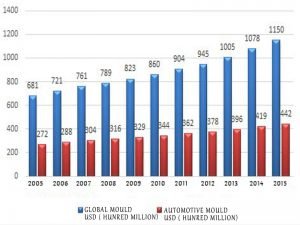

With the increase in the development of new models for passenger cars, many new models launched expansions every year. The capacity of the automotive mold market will increase in the future as the automotive market grows and competition in the automotive market increases. This is also the result of rapid development in the automotive industry and the rapid development of new models.

Luo Baihui, general secretary of the International Model Association, said that market demand for automotive panel mold depends mainly on the number of new models to be launched each year, and the number of new models to be delivered depends primarily on recent model development efforts of passenger cars (including car, MPV, SUV, and minibus with less than nine seats, etc.).

According to the automotive manufacturer’s cover parts and requirements category, the automotive cover mold can be divided into three grades: low end, middle end, and high end. Among them, molds with low technical content have been oversupplied. The market profit margin is narrow; the competition in the mid-end mold market is becoming increasingly fierce, and high-end high technical content is far from meeting the market demand have colossal development space.

Have Mould has formed a set of self-own automotive mold systems for producing automotive mold.

Three-dimensional design

Three-dimensional design

High-end automotive stamping die manufacturing, from a design aspect, needs a parametric design of the mold. We need to combine software template technology to actively and effectively achieve secondary development, form a series of fixed, standardized design parameters and design templates, and achieve complete correlation and drive of parameters what’s mean to change CAE result, mold process, and optimization of mold structure quickly through a change of parameter of mold parts.

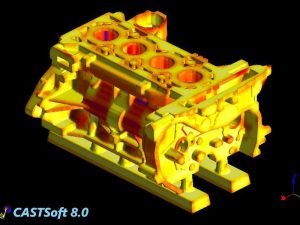

Simulation of stamping process – Computer-Aided Engineering (CAE)

Manufacture of automotive mold is inseparable from an effective board forming simulation software, and high-end automotive mold requires finite element simulation technology for the whole process. Effective board-forming simulation software can improve the success rate of high-end automotive mold development and considerably shorten the manufacturing cycle of high-end automotive mold development. It can simulate and analyze the formability of automotive stamping parts, determine the difficulty of forming, and the key areas that can quickly appear stamping quality defects. On the other hand, it can also calculate roughly automotive stamping parts; secondly, it can also be used for selective and targeted simulation analysis for structural and process plans of automotive mold, provide quantitative analysis and judgment data for automotive mold commissioning, identify feasible commissioning solutions and provide specific technical parameters to the solution. In short, the finite element simulation of the whole process can repeatedly optimize the automotive mold structure and process plan; moreover, we can adopt multiple simulations. It can be used before on-site mold debugging to quantitatively analyze and validate the feasibility and reliability of automotive mold design, timely optimize, and improve mold design.

Digital mold technology

Digital automotive mold technology mainly includes the following aspects: 1, Design for manufacturability (DFM), which considers and analyzes manufacturability during design to ensure the success of the process. 2, The auxiliary technology of mold surface design develops intelligent profile design technology. 3, CAE additional analysis and simulation of stamping process, predict and resolve possible defects and forming problems. 4, Replace the traditional two-dimensional design with a three-dimensional mold structure design. 5, Mold manufacturing process using CAPP, CAM, and CAT technology. 6 Under the guidance of digital technology, solve the problems that arise during the test die process and stamping production.

Mold processing automation

Have Mould is equipped with CNC machines with a double table, automatic tool changers (ATC), photoelectric control systems for mechanical machining, and online measuring systems for workpieces. CNC machining has evolved from simple profile machining to complete profile and structural surfaces, from medium to low-speed to high-speed machining.

Mold material and surface treatment technology

The quality and performance of mold material are essential factors that affect the mold’s quality, life, and cost. Ductile iron has good toughness and wears resistance, welding performance, workability, and surface hardening. Moreover, the price is lower than that of alloy cast iron. It has been widely used in Have Mould’s mold design.

Scientific and information management

Scientific management keeps Hafo Mould developing in the direction of Just-in-Time Manufacturing and Lean Production. Enterprise management is more precise, and production efficiency is greatly improved.

Multi-position progressive die

The multi-position progressive die can complete multiple stamping processes for parts, including punching, bending, drawing, and forming with partial separation and continuous forming. The mold must have high-precision guidance, a fixed distance system, automatic feeding, automatic output, safety detection, and other devices. At the same time, the mold structure is complex, with many inserts, high mold manufacturing precision, complex manufacturing, and assembly process. It is an essential representative of the technology-intensive automotive mold.

With the advent of electric vehicles, driverless technologies, and new energy vehicles, energy conservation, environmental protection, artificial intelligence, and vehicle networking technologies have become increasingly important in the automotive industry. The rapid development of the new energy vehicle market led to an increase in new models, which has brought substantial market opportunities to the mold industry.

As new energy vehicles emphasize reduction and efficient use of energy, lightweight materials have great potential in the market. For example, in TESLA Model S, 95% of body structure parts are made of aluminum alloy; Enough to see the application of new materials in lightweight have become one of the core technical directions in the future, especially the development of lightweight metal forming, polymer material forming, and composite forming.

At the same time, with the rapid development of vehicle networking technology, continuously improved electrification, and intelligence degree, the automotive electronic mold has also ushered in a broader market space. China’s automotive electronics mold companies are actively deploying car networking services and critical components and high-value-added products such as integrated circuits, forming synergies with the automotive electronics industry. Under the background of the rapid development of new energy vehicles and smart cars, enterprises that can use the mold to manufacture Intelligent Driver Interactive Vehicle products and high-end functional assemblies will have colossal development space!

The steady and rapid development of the automotive industry has created a suitable environment for developing the automotive stamping die industry. More than 90% of parts need to be formed by the mold in the automotive production process. It takes more than 1,000 to 1,500 sets of stamping dies to make a car. A country’s car production reflects the overall situation of the country’s required automotive molds. After the 2008 financial crisis, automotive production in traditional automotive production countries such as the United States, Germany, and Japan recovered moderately, while demand in emerging markets such as China, India, and Brazil increased. According to forecasts, the global light vehicle production growth rate will reach 3.6% from 2013 to 2020, of which the growth rate of developing countries will get 5.7%, the growth rate of developed countries will remain at around 1.2%, and the steady development of downstream automotive industry created an excellent environment to the development of automotive mold.

Three-dimensional design

Three-dimensional design