An Injection Mold Factory Providing Injection Molding and Tooling Services, Rapid Prototyping, and CNC Machining Services in China

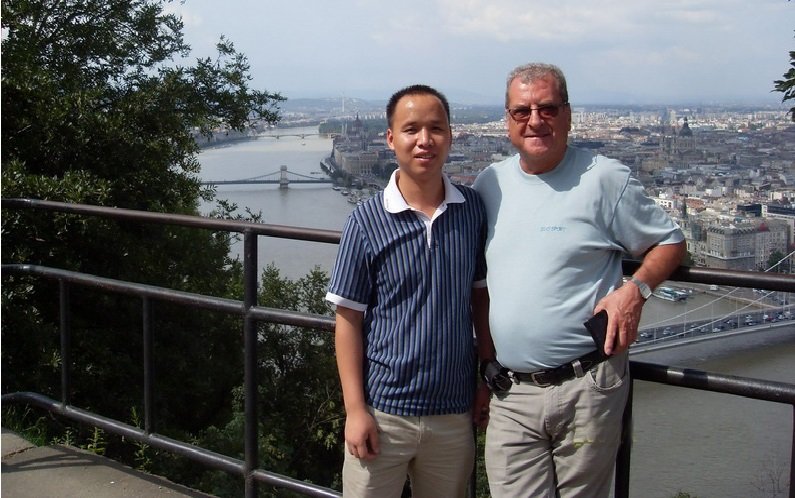

Haifu Mould Industry Limited is a renowned injection mold factory with over 15 years of experience in providing precision injection molding and tooling solutions. As a trusted partner for businesses across various industries, we have successfully delivered high-quality, cost-effective products that cater to the unique requirements of our clients. Our expertise spans across automotive, electronics, medical, and consumer goods sectors, making us a top choice for businesses seeking reliable injection molding services.

The primary injection molds we make are listed below:

We understand the diverse needs of different industries and have developed a wide range of mold solutions to cater to their specific requirements. Our injection mold factory has extensive experience in creating custom molds for:

Automotive: We design and manufacture high-precision molds for various automotive components, ensuring durability, performance, and safety.

Electronics: Our expertise in creating intricate molds for electronic components helps clients achieve optimal product functionality and reliability.

Medical: We adhere to strict quality control measures to produce medical-grade molds that meet the highest industry standards for safety and hygiene.

Consumer Goods: Our injection mold factory develops innovative mold solutions for everyday products, enhancing their usability and aesthetic appeal.

Many well-known businesses, including DURA Automotive Systems, Brose Fahrzeugteile GmbH & Co, Precise Global Pty Ltd, Purafil Inc, ANVA Polytech, Aditya Auto Products & Engineering (I) Pvt. Changfei, Hafei, Lifan, and Ford in China are among those with which we have long-standing business relationships. The United States, Europe, the Middle East, and other nations are the primary destinations for our mold exports.

We cordially invite you to come to our facility and grow your business!

MOULD DESIGN

ur team of skilled engineers and designers at Haifu Mould work closely with clients to develop tailor-made mold solutions that meet their exact specifications. Utilizing cutting-edge software and equipment, we ensure that our mold designs are optimized for efficient production and consistent product quality. Our injection mold factory is committed to continuous improvement and innovation, staying at the forefront of the latest industry trends and technologies.

QUALITY

e take quality control very seriously. Our injection mold factory implements rigorous testing and inspection processes to ensure that every component we produce meets or exceeds our client’s expectations. Our comprehensive quality control measures include the following:

Material Inspection: We carefully select and inspect raw materials to ensure their suitability for the intended application.

In-Process Inspection: Our team closely monitors the production process to identify and address potential issues early on.

Final Inspection: Before shipping, we thoroughly inspect the finished products to ensure they meet the highest quality standards.

MAIN QC PROCEDURE

1. Mould Design Control

2. Mould Steel Hardness Inspection

3. Mould Electrodes Inspection

4. Mould Core and Cavity Steel Dimension Inspection

5. Mould Pre-Assembly Inspection

6. Mould Trial Report and Samples Inspection

7. Pre-Shipment Final Inspection

8. Export Product Package Inspection

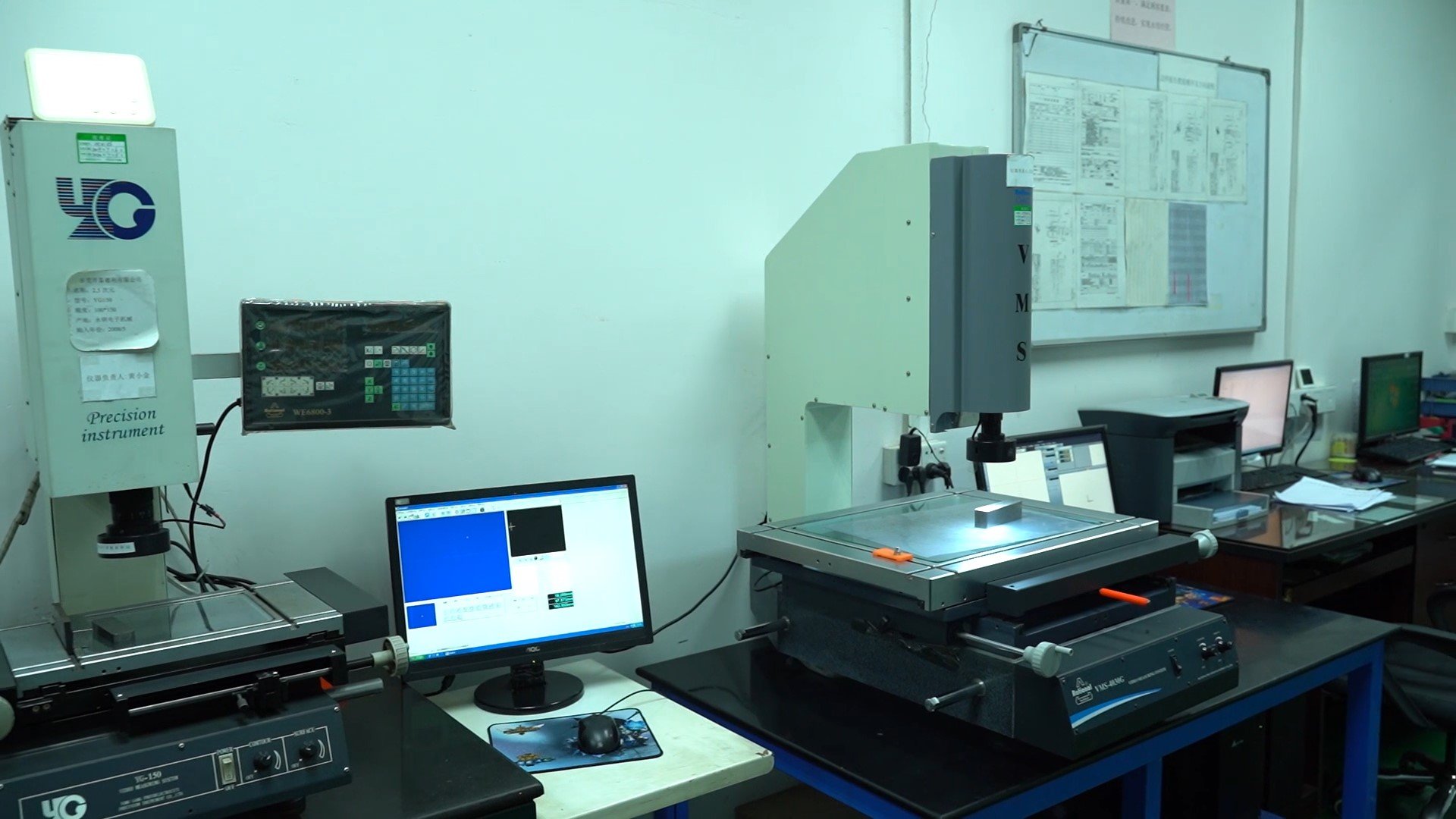

MAIN QC EQUIPMENT

1. CMM Machine

2. Optical Projector

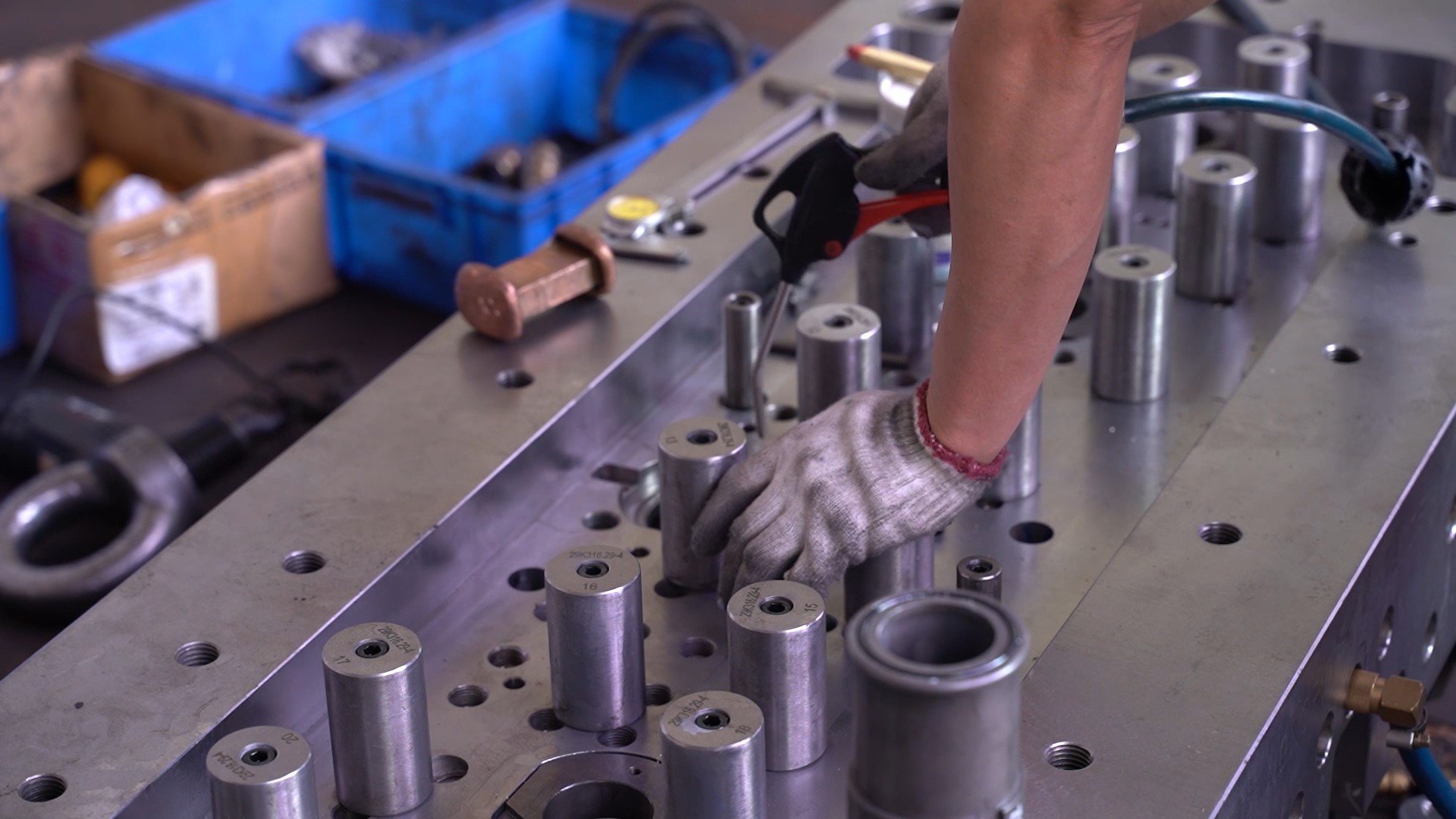

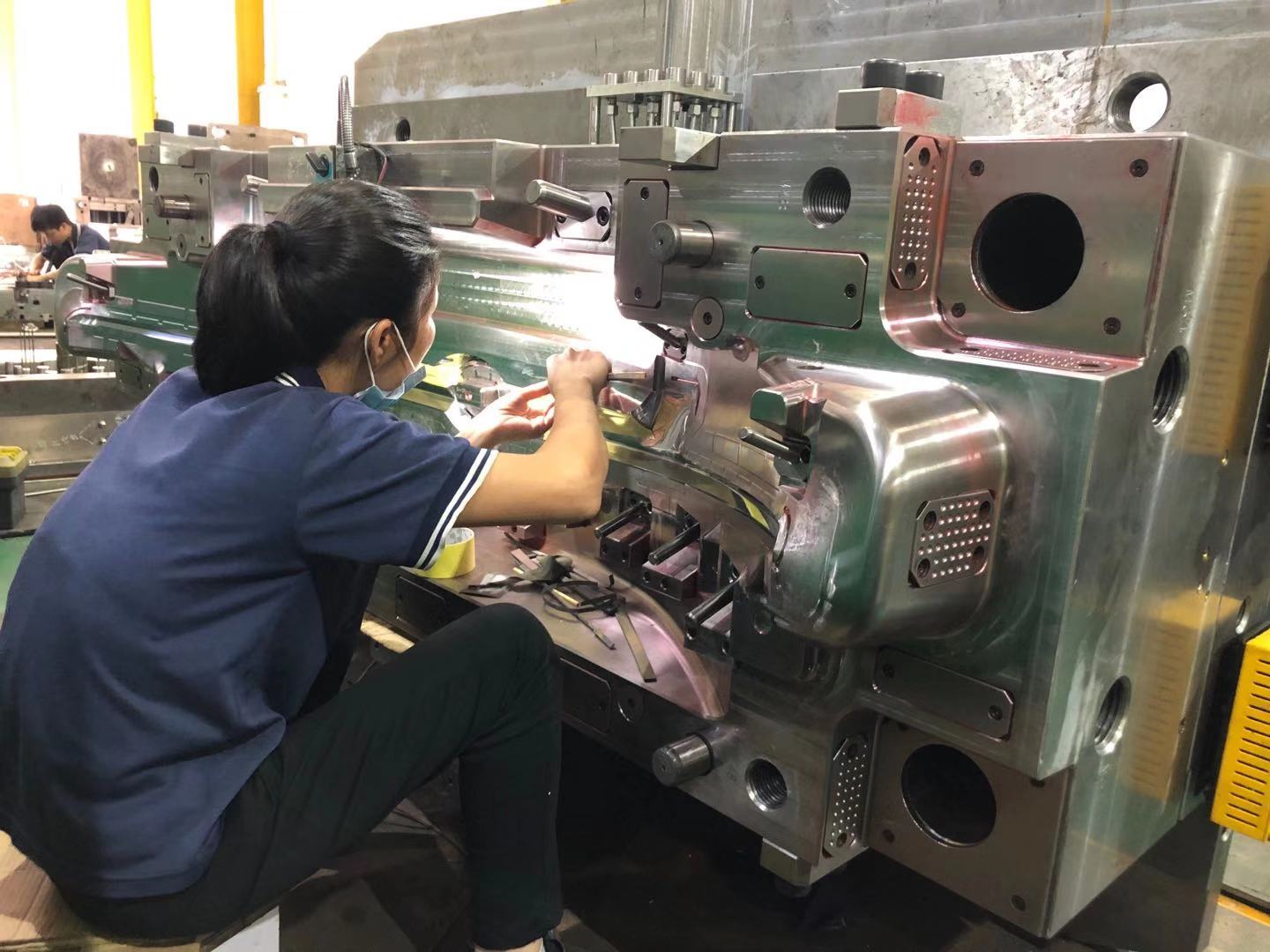

HAFO’S WORKSHOP

HAFO’S CUSTOMERS