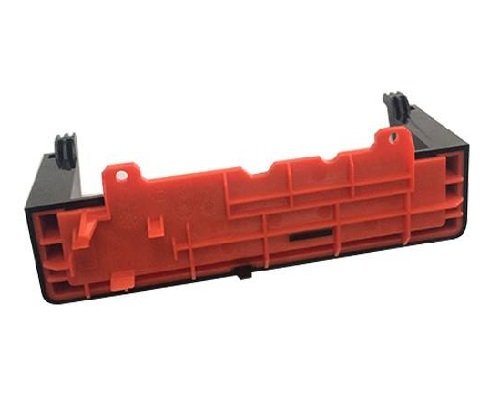

Two-Shot Mold

Item name: Two-Shot Mold

Material:

Size:

OEM/ODM Service

Lead time: 30-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms: T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Two Shot Injection Mold: A Comprehensive Guide

Are you looking for an efficient and cost-effective way to produce complex plastic parts for your product design? Look no further than two-shot injection molding. In this article, we will explore what two-shot injection molding is, how it works, its advantages and disadvantages, as well as its applications and considerations.

Introduction

Injection molding is a widely used manufacturing process for producing complex plastic parts. It involves melting plastic pellets and injecting them into a mold under high pressure, where they cool and solidify into the desired shape. However, traditional injection molding has some limitations in terms of design flexibility, material selection, and product quality. This is where two-shot injection molding comes in.

What is Two-Shot Injection Molding?

Two-shot injection molding, also known as multi-shot molding or overmolding, is a manufacturing process that produces a complex plastic part in two or more colors or materials using a single mold. This process involves injecting two different materials into a single mold, one after the other, to create a part with multiple layers or components.

How Does Two-Shot Injection Molding Work?

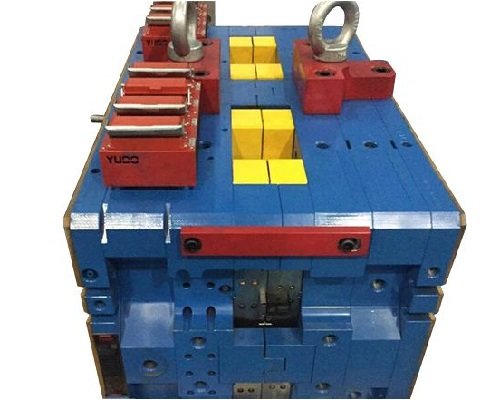

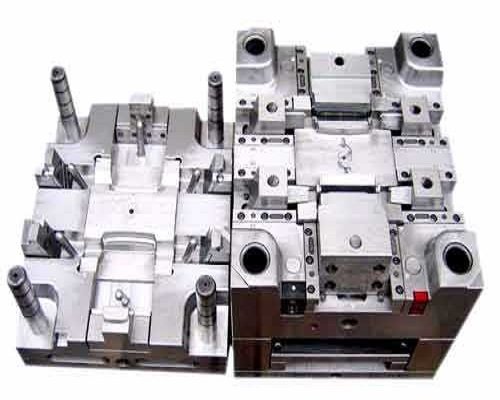

The two-shot injection molding process consists of several steps. First, the mold is prepared with the necessary cavities and gates. Then, the first material is injected into the mold, filling the designated area. Once the first material has cooled and solidified, the second material is injected into the same mold, bonding with the first material to create a multi-layered or multi-component part.

Advantages of Two-Shot Injection Molding

Two-shot injection molding offers several advantages over traditional injection molding:

Increased Efficiency

Two-shot injection molding eliminates the need for secondary assembly or bonding processes, reducing manufacturing time and costs.

Improved Design Flexibility

Two-shot injection molding allows for more complex and intricate designs that are difficult to achieve with traditional injection molding.

Enhanced Product Quality

Two-shot injection molding produces parts with a higher level of precision, consistency, and durability, resulting in higher product quality.

Reduced Costs

Two-shot injection molding reduces costs associated with secondary assembly, bonding, and labor, resulting in a more cost-effective manufacturing process.

Disadvantages of Two-Shot Injection Molding

Two-shot injection molding also has some disadvantages to consider:

Limited Material Selection

Two-shot injection molding is limited to certain materials that can bond together, restricting the range of materials that can be used.

Higher Initial Investment

Two-shot injection molding requires specialized equipment and tooling, resulting in a higher initial investment than traditional injection molding.

Applications of Two-Shot Injection Molding

Two-shot injection molding has a variety of applications across different industries, including:

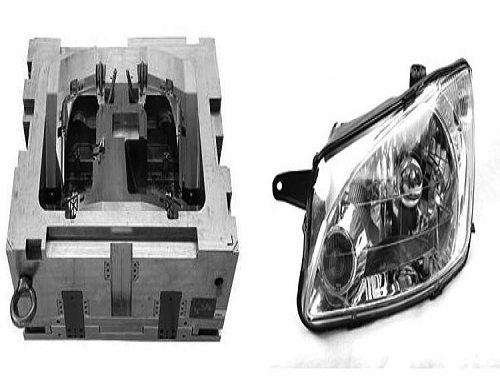

Automotive Industry

Two-shot injection molding is used to produce various automotive parts, such as interior trims, buttons, and knobs.

Medical Industry

Two-shot injection molding is used to produce medical devices and equipment, such as syringes, inhalers, and surgical instruments.

Consumer Electronics

Two-shot injection molding is used to produce parts, such as phone cases, remote controls, and buttons for electronic devices.

Considerations for Two-Shot Injection Molding

Before choosing two-shot injection molding as your manufacturing process, there are several considerations to keep in mind:

Material Selection

Since two-shot injection molding requires two materials that can bond together, the choice of materials is limited. It is important to select materials that can withstand the injection process and produce the desired properties in the final product.

Tooling Design

Two-shot injection molding requires specialized tooling with multiple cavities and gates to accommodate the two materials. The tooling design needs to take into account the specific part geometry and material properties to achieve the desired outcome.

Manufacturing Process

Two-shot injection molding requires precise control over the injection parameters and timing to ensure proper bonding and layering of the materials. The manufacturing process also involves additional steps for cleaning and maintenance of the equipment.

Conclusion

Two-shot injection molding is a cost-effective and efficient manufacturing process that offers improved design flexibility and enhanced product quality. While it has some limitations and considerations to keep in mind, its applications across various industries make it a viable option for complex plastic part production.

FAQs

- What materials can be used in two-shot injection molding?

- Two-shot injection molding is limited to materials that can bond together, such as thermoplastics and thermoplastic elastomers.

- Is two-shot injection molding more expensive than traditional injection molding?

- Two-shot injection molding has a higher initial investment but can reduce costs associated with secondary assembly and labor, resulting in a more cost-effective manufacturing process.

- What industries use two-shot injection molding?

- Two-shot injection molding is used across various industries, including automotive, medical, and consumer electronics.

- What are the advantages of two-shot injection molding?

- Two-shot injection molding offers increased efficiency, improved design flexibility, enhanced product quality, and reduced costs.

- What are the considerations for two-shot injection molding?

- The considerations for two-shot injection molding include material selection, tooling design, and precise control over the manufacturing process.