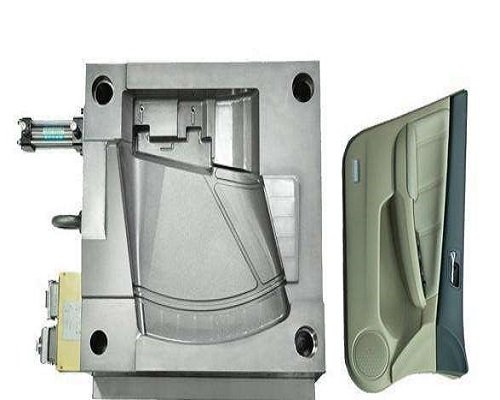

Car Door Mould

Item name: Car Door Mould

Material:

Size #

OEM/ODM Service #

Lead time: 55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Car Door Plastic Mold

Car manufacturing is a complex process that involves the use of various components. One of these components is the car door, which is often made of plastic. The use of plastic in car doors offers many advantages, such as cost-effectiveness, durability, and design flexibility. To produce high-quality plastic car doors, you need a car door plastic mold. This article will provide you with all the necessary information about car door plastic molds.

Benefits of Car Door Plastic Mold:

The use of car door plastic mold has many benefits, such as:

Cost-effectiveness

One of the main advantages of using car door plastic molds is their cost-effectiveness. Compared to other materials, plastic is much cheaper and easier to work with. Additionally, plastic molds can be reused multiple times, which reduces the overall cost of production.

Durability

Plastic is a durable material that can withstand wear and tear. When properly designed and manufactured, plastic car doors can last for a long time without breaking or cracking.

Design Flexibility

Car door plastic molds offer design flexibility, allowing manufacturers to create unique designs and shapes. This is because plastic can be molded into any shape, size, or color, providing a wide range of design options.

Types of Car Door Plastic Molds:

There are several types of car door plastic molds, including:

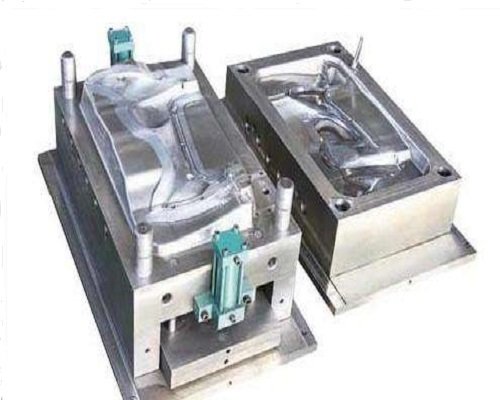

Injection Molds

Injection molds are the most common type of car door plastic molds. They work by injecting melted plastic into a mold cavity, which then cools and solidifies into the desired shape.

Blow Molds

Blow molds work by blowing air into a molten plastic tube, which then expands to fill the mold cavity. Once the plastic cools and solidifies, the mold is removed, and the final product is formed.

Compression Molds

Compression molds are used for larger car door parts. They work by compressing plastic between two heated mold halves until it cools and solidifies.

Manufacturing Process of Car Door Plastic Mold:

The manufacturing process of car door plastic molds involves the following steps:

- Designing the mold: The first step is to design the mold, which involves creating a 3D model of the car door.

- Creating the mold: Once the mold design is finalized, the mold is created using specialized equipment and techniques.

- Injection molding: The next step is injection molding, which involves injecting melted plastic into the mold cavity.

- Cooling and solidification: After the plastic is injected into the mold, it is cooled and solidified.

- Ejecting the part: Once the plastic is cooled, the mold is opened, and the final part is ejected.

Frequently Asked Questions (FAQs):

Q1: What materials are used to make car door plastic molds?

A1: The most common materials used to make car door plastic molds are steel, aluminum, and copper.

Q2: How long does it take to manufacture a car door plastic mold?

A2: The manufacturing time for a car door plastic mold can vary depending on the complexity and size of the mold. However, it can take anywhere from a few days to several weeks.

Q3: How many times can a car door plastic mold be used?

A3: A car door plastic mold can be used multiple times, depending on the quality of the mold and the type of plastic used. Injection molds, for instance, can be used up to millions of times, making them a cost-effective option.

Q4: Can a car door plastic mold be customized?

A4: Yes, car door plastic molds can be customized to suit specific design and manufacturing requirements. Manufacturers can create molds with unique features, such as multiple cavities or undercuts.

Q5: What are the maintenance requirements for a car door plastic mold?

A5: To ensure the longevity of a car door plastic mold, it’s essential to clean and maintain it regularly. This includes inspecting the mold for damage or wear, lubricating moving parts, and storing the mold in a cool and dry place.

Q6: Can car door plastic molds be recycled?

A6: Yes, car door plastic molds can be recycled, depending on the type of plastic used. However, the recycling process can be challenging and may require specialized equipment.