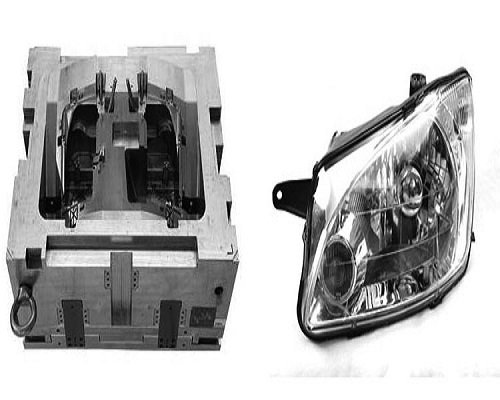

Auto Lamp Mould

Item name: Auto Lamp Mould

Material: PC、PP、ABS、PMMA

Size #

OEM/ODM Service #

Lead time: 25-55days after deposit

Packing Details: wooden box

Payment & Shipping Terms Payment terms :T/T(30% deposit, 70% before shipment)

Shipping Port: guangzhou/shenzhen

Automotive lamp Mold

Automotive lamps are an essential component of a car’s exterior design. They provide functional lighting and serve as a critical element in the car’s overall aesthetic appeal. Automotive lamps have evolved to reflect changing aesthetic trends and incorporate technological advancements.

Today’s Automotive lamps typically include high-beam, low-beam, turn, position, and daytime running lights. With the increasing popularity of LED lighting, the light source for headlamps has transitioned from halogen and xenon to LED, matrix, and laser sources. This has allowed for greater flexibility in design, as well as improved energy efficiency.

Another trend in headlamp design is the move towards thinner, more streamlined shapes. This has posed new challenges for Automotive lamp Mold designers, as eye-catching conditions require more complex molding techniques.

The Challenges of Automotive Lamp Mold Design

Creating molds for Automotive lamp Mold is a complex process that requires a deep understanding of the product’s features and requirements. With the move towards thinner, more intricate designs, Automotive lamp Molds are becoming increasingly complex. Mold drops of around 600 mm-750 mm are becoming more common, and light strip and ring shapes require multi-gate and sequence valve systems to ensure proper molding.

To meet these challenges, Automotive lamp Mold designers are turning to advanced techniques such as electroforming core and diamond cutting to ensure the highest levels of optical quality. Thick wall molds and light guide molds are also becoming more prevalent.

Our Expertise in Automotive lamp Molding

At our company, we have extensive experience in Automotive lamp Mold design and manufacturing. We are intimately familiar with the requirements and challenges of Automotive lamp Mold and have developed the corresponding design standards necessary to meet these challenges. Our flexible approach allows us to create custom solutions for the most complex headlamp mold development needs.

FAQs About Automotive Lamp Molding

What is Automotive lamp Molding?

Automotive lamp Molding refers to the process of creating molds for the Automotive lamp of automobiles. This complex process requires a deep understanding of the product’s features and requirements.

What are the latest trends in Automotive lamp design?

The latest trends in headlamp design include using LED, matrix, and laser sources and moving toward thinner, more streamlined shapes.

What are some of the challenges of Automotive lamp Mold design?

Creating molds for Automotive lamps is a complex process that requires a deep understanding of the product’s features and requirements. With the move towards thinner, more intricate designs, Automotive lamp molds are becoming increasingly complex.

What techniques are used in Automotive lamp Mold design?

Automotive lamp mold designers are turning to advanced techniques such as electroforming core and diamond cutting to ensure the highest levels of optical quality. Thick wall molds and light guide molds are also becoming more prevalent.

How important is the design of a car’s Automotive lamp?

The method of a car’s Automotive lamp is essential to its overall aesthetic appeal. It provides functional lighting and is critical to the car’s overall design.

Why is it important to choose a reliable Automotive lamp molding company?

Choosing a reliable Automotive lamp molding company is essential to ensuring the highest levels of quality and precision in Automotive lamp mold design and manufacturing.