Classification of two shot injection molding

Two shot injection molding: Two kinds of plastic materials are molded on the same injection machine and molded in two parts, but product only molds once. Generally this double injection molding process is also called double-material injection molding, usually consisting of two molds, one half mounted on fixed plate of machine, and the other half mounted on rotary plate. Male molds of these two molds are exactly same, female molds is different. When plastic of the first color is injection molded, male and female molds are opened once. Then male mold is rotated 180 degrees with product once, reaching position of the second color injection molding, and performed to obtain the two-color workpiece. There will be semi-finished products and finished products in each molding cycle.

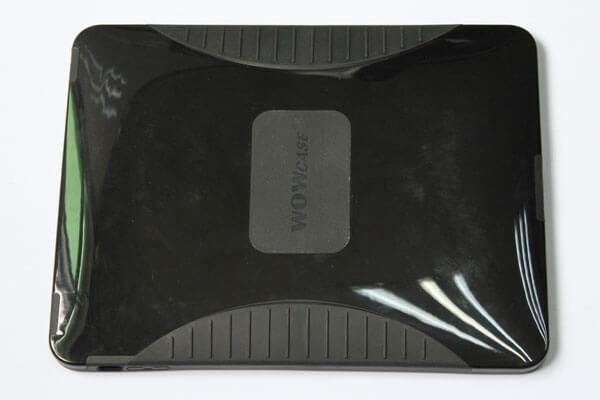

Insert Molding: Sometimes called fake two shot injection molding, two kinds of plastic materials are molded on different injection molding machines and molded in two parts. Products are taken out from a set of mold and then placed in another set of mold. The second injection molding (so we call the first shot is insert). Typically this double injection molding process is typically done with 2 sets of molds without need for a special two-color injection molding machine.

Choose a two shot injection molding, generally no more than following situations.

1) Product function requirements. For example, power switch, mobile phone button, keyboard indicator, car switch, etc. Part of LED is required to be transparent. For example, power switch button, LED light.

2) Improve feeling. Some handheld products require use of Rubber in hand-held part, which makes hand feeling more comfortable. For example, walkie-talkie case, power tool handle, wrench, screwdriver handle, toothbrush handle, vacuum flask, etc.

3) Add beauty. For example, as an ornament, if you use two-color injection molding, it is beautiful and you don’t have to worry about it being rubbed off.

4) Partial area of product that needs electroplating. In the plastic family, only ABS and polysulfone (PSU) surfaces can be plated. If local or single side of product is required to be plated, plating area should be injected into ABS, and the area that no plating is required is injected into other materials such as PC.

Requirements of Two shot injection molding design

Two shot injection moldings are very common on the plastic molding manufacturing market today because it can make appearance of product more beautiful and is easy to change colors without spraying. Main points of two shot injection molding design are summarized as follows:

1) Two shapes of cavity are different, forming one product separately, and two shapes of core are exactly same.

2) Front and back molds must be aligned after being rotated 180 degrees from center. This must be checked during design.

3) Pay attention to position of top stick hole, minimum distance is 210mm. Large molds must be appropriately increased in the number of jack holes. Moreover, since top stick attached to injection molding machine itself is not long enough, we must design a long top stick in our mold, and top stick grows about 150 mm from bottom of mold base. Two positioning rings must be designed on the bottom plate of back mold.

4) Total thickness of front mold panel plus A board should not be less than 170mm. Please review other reference data for this type of injection molding machine, such as maximum die thickness, minimum die thickness, and top hole distance.

5) Nozzle of three-plate mold can be designed to automatic demoulding. Pay special attention to reliable demoulding of soft glue nozzle.

6) Depth of front side SPRUE should not exceed 65mm. Distance from top of the upper side (large nozzle) SPRUE to center of mold base is not less than 150 mm.

7) When designing cavity of second injection molding, some parts can be designed to avoid the CAVITY insert (or rubbing) injury to the first molded product glue position. However, strength of each seal position must be carefully considered, that is whether plastic mold parts will be deformed in the injection under a large injection pressure, which may result possibility of burr in the second injection.

8) When injection, size of the first injection product can be slightly larger, so that it can be pressed tighter with another CAVITY in the second molding to achieve the sealing effect.

9) Note that in the second injection, whether flow of plastic will impinge on the first molded product, so that plastic position is deformed. If this is possible, we must find a way to improve it.

10) Before clamping A and B plates, make sure if slider and lifter of the front die will reset first to crush product. In this case, it is necessary to find a way to clamp A and B boards first, and then Slider or lifter of the front mode can be reset.

11) The water transport layout of these two CAVITY and CORE must be as full as possible and balanced.

12) Mostly inject hard plastic mold part of product first, and then soft rubber part. Because soft rubber is easy to deform.

13) In order to make two plastics “stick” tighter, consider “stickiness” between materials and roughness of mold surface. Two-color injection molding has a special TPU. The smoother the mold surface, the more “sticky” they are.

14) Pay attention to positioning of front and rear molds in plastic molding manufacturing; all insertion and slope of broken surface should be as large as possible and more than 0.1mm.