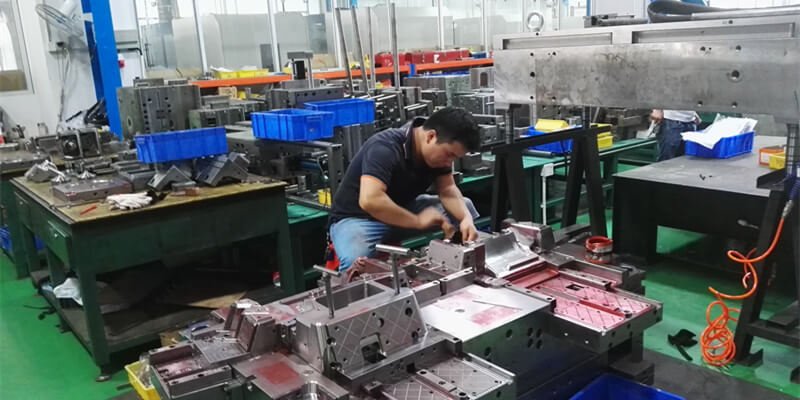

Production of most rubber products is inseparable from use of molds. Mold is determinant of shape for product and key factor in ensuring inherent quality of finished product. In long-term use process, solid residual dirt is inevitably formed on the surface, and dirt on rubber moulding dies is thickened with time, which not only affects appearance of product and accuracy of outer edge size of product, but also heat transfer effect. Therefore, regular maintenance and maintenance of rubber moulding dies is a compulsory course for china rubber molding factory who provide rubber moulding services. Which includes:

First, regularly maintained mold wear curve which is present in each mold. Mold repair is an abnormal wear in the field of realization, and amount of press processing is easy to learn during this time. When number of processing is met, maintenance of rubber moulding dies and the maintenance plan are not only easy to learn maintenance items, but also easy to control maintenance time.

Second, improved maintenance to extend life of rubber injection molding, stability of quality, easy maintenance, etc., and to improve partial mold special maintenance.

Third, routine maintenance refers to normal rubber mold cleaning, inspection, and moving to oil. This work usually confirms that mold is in a normal state and can detect anomalies early.

Fourth, rubber moulding dies processing for accident state maintenance will have some changes, and it cannot continue to be used in formation process. For example, large burrs and wrong size, such as scars, burning of mold parts. Similar abnormality cause repair and maintenance of mold, it is called an accident. This type of maintenance is usually used up to near limit. Because this is a sudden maintenance, there must be a device in the planned stop, and emergency repairs.

At present, cleaning and maintenance of china rubber molding factory to provide rubber moulding services mainly use chemical cleaning method. When dirt composition is complex, it is necessary to repeatedly clean by cleaning agent. Long-term use will cause rubber injection molding to corrode, thus affecting appearance and quality of product. Another widely used method is mechanical cleaning, but it will cause damage to mold during cleaning process such as scraping, rubbing, brushing, sand blasting, etc. In addition, it requires repeated loading and unloading, which is labor intensive and time consuming. Below we will introduce the most effective method in the cleaning of rubber injection molding – ultrasonic cleaning.

How an ultrasonic mold cleaning works

- Ultrasonic cleaning is a physical cleaning, which itself is green cleaning. If a suitable cleaning agent is added to cleaning solution, it is a combination cleaning, which has a more obvious cleaning effect.

- Ultrasonic waves mainly have mechanical effects, thermal effects, and cavitation effects. When ultrasonic wave is forwardly spread in liquid in the form of alternating positive pressure and negative pressure, an innumerable small amount of small bubbles are formed in liquid (cleaning solution), and these bubbles are formed, grown in negative pressure region of longitudinal propagation of ultrasonic wave, but quickly closed in the positive pressure zone. In this process known as “cavitation” effect, bubble closure can produce an instantaneous high-pressure jet of far more than 1000 atmospheres and a high temperature approaching 5000 degree. Continuous generation of high-pressure energy is like a series of small explosion continuously impacts surface of object, so that dirt on the surface and gap of object is quickly peeled off and eliminated. Thereby achieving ideal state of making surface of object clean.

- Number of bubbles generated in liquid due to cavitation is numerous and ubiquitous, so cleaning of workpiece can be very thorough. Even inside a workpiece with a complicated shape, as long as it can be contacted with the solution, it can be thoroughly cleaned.

Ultrasonic cleaning advantages

- Ultrasonic cleaning is fast, high quality and easy to automate. It is especially suitable for workpieces with complex surface shapes such as for holes, slits, grooves, micropores, dark holes on precision workpieces with which usual scrubbing method is difficult to achieve, and ultrasonic cleaning can achieve good results;

- Ultrasonic cleaning has better cleaning effect on materials with hard texture and strong sound reflection (such as metal, glass, ceramics, plastic);

- High cleanliness and consistent cleanliness of all workpieces;

- Cleaning speed is fast, production efficiency is improved, and cleaning liquid is not required to be touched by human hands, which is safe and reliable;

- No damage to surface of workpiece, saving solvent, heat, work site and labor.

Compared with other cleaning methods, ultrasonic cleaning method not only reduces labor intensity, but also saves cleaning time and avoids damage of rubber moulding dies. This is especially important for high-precision molds that do not allow any damage. Ultrasonic cleaning molds are a more effective means of cleaning in a variety of chemical, physical, and mechanical applications.