Automotive mold refers to mold that used in the automotive field, and is known as “mother of automotive industry”. More than 90% of parts in automobile production rely on mold forming. The most important component of automotive mold is cover mold. This type of mold is mainly a cold die. In a broad sense, auto mold is a general term for mold that makes all the parts on a car. For example, stamping dies, injection mold, forging die casting mold, casting wax dies, glass dies, and so on.

Stamping on automotive bodies are broadly divided into cover members, beam members, and general stamping. The stamping that can clearly represent the characteristics of a car is a car cover. Therefore, the more specific automotive molding can be said to be “automotive cover stamping die”. Such as front door outer panel trimming mold, front door inner panel punching mold.

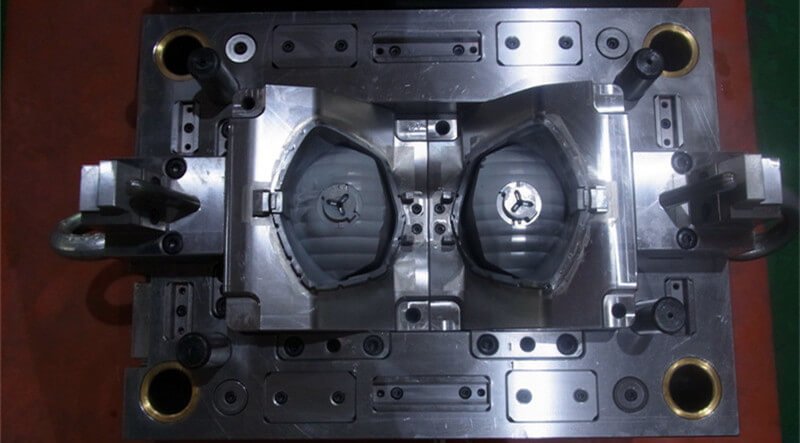

Automotive body mold, especially large and medium-sized cover mold, an important part of body manufacturing technology and a key link of auto development capabilities. Automotive molding products include automotive cover mold, tire mold, interior and exterior plastic injection molding, lamp mold, automobile bumper mold, and automobile dashboard mold.

In the developed countries such as Germany, United States, Japan and other automobile manufacturing industries, more than 40% of mold industry’s products are auto mould, and only about one-third of mold products in China serve automobile manufacturing industry. In general, manufacture of a regular car requires about 1,500 molds, of which nearly 1,000 stamping die casting mould and more than 200 interior die casting mold. Affected by rapid development of China’s auto industry, China’s automotive mould industry is growing rapidly and market capacity is expanding. And with continuous optimization of industrial structure of China’s automotive molding industry and continuous advancement of technology, proportion of high-end auto mould products in the entire industry has gradually increased, and average annual growth rate is expected to exceed 15% in the next five years.

Automobile stamping die casting

Automobile stamping die casting is the important process equipment for automobile production. Its design and manufacturing time accounts for about 2/3 of automobile development cycle, which is one of the main constraints of automobile replacement. Automobile stamping dies have characteristics of large size, complicated working surface and high technical standards, and are technically intensive products. In the past, automobile stamping die casting mold generally adopted structural design of single-process and composite dies, and with advancement of technology and improvement of equipment level, multi-station mold and progressive dies that can reduce costs and improve production efficiency are gradually applied to automobile stamping die casting moulding. In the design and manufacture, it has become development direction of automotive stamping die manufacturing technology.

Since 2001, global mold industry has been steadily rising, with an average growth rate of more than 5%. By 2012, global mold industry market reached 94.5 billion US dollars. In developed countries such as United States, Germany and Japan, automotive-related mold demand accounts for more than 40% of total mold demand. Based on this estimate, global automotive molding market has reached US$37 billion. According to proportion of automobile stamping die casting mold production value to 40% of automobile molding production value, global automotive stamping die casting mould market is about 15 billion US dollars. At present, North America, Europe, and Japan, as traditional demand market for automotive stamping die casting moulding, still occupy an important position in global demand, and their market demand growth rate will remain at a relatively stable level in the next few years. Compared with developed countries such as United States, Germany and Japan, automobile industry in emerging economies such as China, India, Brazil and Russia is developing rapidly, and related demand has expanded demand space of global automotive stamping die casting mold market, and will gradually become a new engine for mold demand growth in global automotive stamping casting mold market.

About tire mold

Among them, tire mold, as part of automobile mold, has played an important role. From perspective of models used, tires can be divided into tires for passenger cars and heavy-duty tires for trucks, as well as special tires for construction machinery. The proportion of passenger tires is the largest. From global tire data, growth rate of passenger tires is ahead of heavy-duty tires. As infrastructure construction of emerging economies recovers (such as China), heavy trucks are expected to further ease inventory pressure and benefit heavy-duty tires.

Combining global tire production trend and real situation of domestic tire market, we expect that tire industry will enter a stage of moderate growth in the future. In the long run, growth rate of tire production in developed countries such as Europe and United States is due to strict legislation and high stocks. In the long run, it is expected to reach 1.2%. As production of high-speed cars in Asia, Africa and Latin America is not sustainable, we expect growth rate of global tires to increase by 0.8%.

From perspective of overall industrial chain, tire molding industry has little space, but for entire automotive process, tire mold is a key link. Tire molding industry is small, and global market size is estimated to be between 115 and 15 billion yuan (average of 13.3 billion yuan). Considering linear relationship between tire molding industry and tire production, we assume that annual compound growth rate of tire mold industry is 1.5 times annual compound growth rate of tire production in the next five years, and CAGR is about 1.2% (because of tires). Trend of personalized customization, production of same number of tires in the future requires more molds), by 2020, global tire mold industry market size of about 14.1 billion yuan.